In the modern automotive era, diesel engines are no longer just about raw durability. Today, they are marvels of precision engineering, particularly with the advent of Common Rail Systems.

One of the most frequent questions we receive from our customers is: "How fine are your filters?" or "What is the micron rating?"

This article explores why that "micron number" is critical and why selecting a fuel filter is not just about physical fitment—it is a complex engineering science.

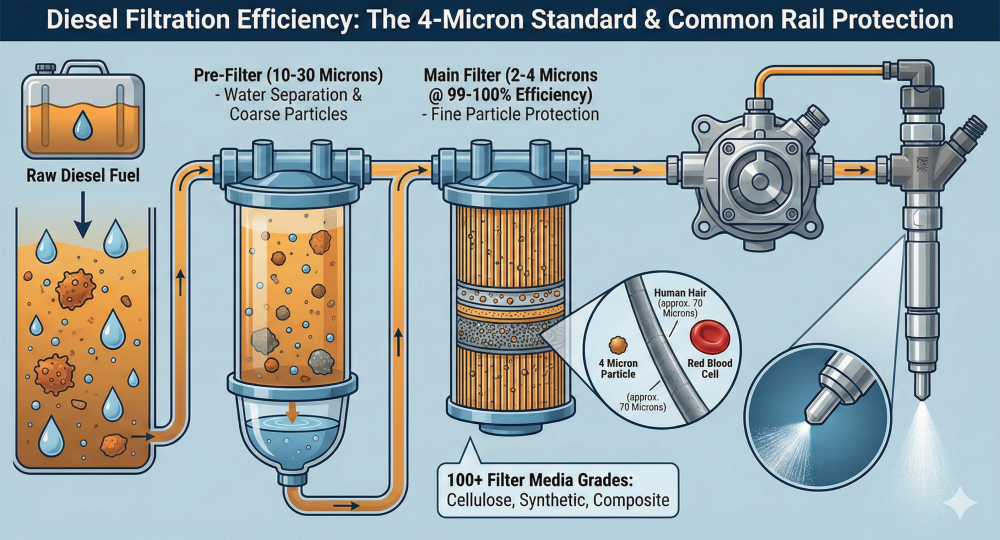

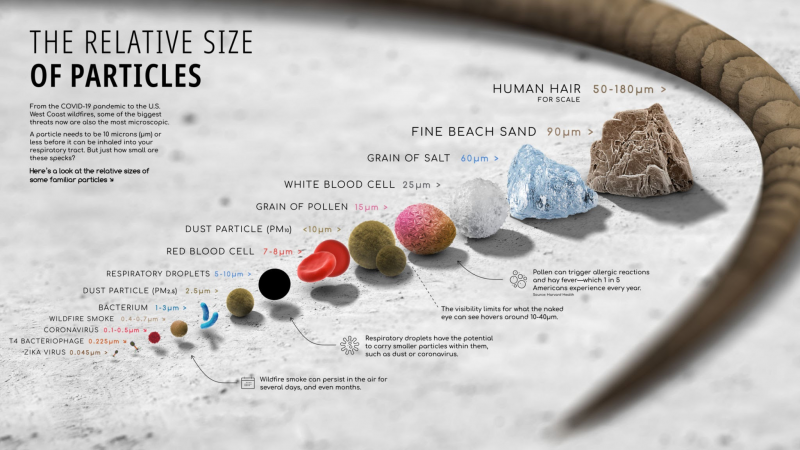

Modern Common Rail fuel injection systems operate at colossal pressures—often exceeding 2,500 bar. To put this in perspective, the injection nozzle orifices are smaller than a human hair.

At these extreme pressures, even microscopic dust particles invisible to the naked eye act like "high-velocity projectiles." If they bypass the filter, they cause rapid erosion (acting like sandpaper) on the nozzle needle and body. This leads to leaking injectors, poor atomization, excessive black smoke, and potential engine failure.

Therefore, a fuel filter is not just a sieve; it is the "Final Line of Defense" that must perform perfectly.

Many assume a filter simply "catches dirt." However, in engineering terms, we evaluate quality based on two key metrics:

This measures the size of the particles the filter can capture.

The Question: "What is the micron rating?"

Our Answer: For modern Common Rail engines, we utilize filter media with a fineness of up to 4 Microns. (For comparison, a human red blood cell is about 8-10 microns, and a human hair is 50-70 microns).

Stating "4 microns" is not enough. We must ask: "At what efficiency percentage?"

Standard Filters: Might capture only 50% of 4-micron particles (letting half pass through).

Our Premium Filters: In our high-spec range, we achieve 99-100% filtration efficiency at the 4-micron level (tested to ISO standards). This distinction is what keeps your engine safe.

A common misconception is that "finer is always better" in every location. This is incorrect. Heavy-duty machinery and modern vehicles often employ a 2-Stage Filtration System:

Location: Before the fuel lift pump or before the main filter.

Function: Handles raw fuel from the tank. Its primary job is Water Separation and trapping larger contaminants.

Fineness: Typically 10-30 Microns. This prevents premature clogging and ensures a steady Fuel Flow Rate.

Location: The final checkpoint before the high-pressure pump and injectors.

Function: Captures the ultrafine particles that damage the injection system.

Fineness: This is where the 2-4 Micron (at 100% efficiency) standard is applied.

The Takeaway: You must use the right filter for the right stage. Using a fine filter in the pre-filter stage will cause rapid clogging, while using a coarse filter in the main stage will destroy your injectors.

Why are we confident in our quality? Because we strictly adhere to the principle: "Select according to Manufacturer (OEM) Specifications."

Every vehicle model and engine brand has unique requirements regarding operating pressure and Flow Rate.

If the media is too dense/tight: The engine starves for fuel, causing power loss.

If the media is too porous/loose: Contaminants pass through, damaging components.

This is why our company stocks over 100 different grades of Filter Media. We do not use a "one-size-fits-all" paper. We meticulously select materials, including:

Cellulose: For standard applications.

Synthetic: For ultra-fine filtration and extended service life.

Composite: For superior water separation capabilities.

We match the "Media Grade" to the "Vehicle Model" to achieve the perfect balance between Cleanliness and Flow.

Beyond solid particles, a high-efficiency filter must combat two primary threats:

Hard Particulates: Rust from tanks, silica, or dust from transport. These cause abrasive wear inside pumps and injectors.

Water: The "Achilles' heel" of diesel engines. A superior filter must have high Water Separation Efficiency. Water causes immediate corrosion, injector tip damage, and promotes bacterial growth in the fuel.

Choosing a low-efficiency fuel filter or one that doesn't meet OEM specs might save a small amount of money today. However, it comes with the high risk of expensive repairs for injectors or fuel pumps in the future.

At our company, we don’t just sell filters; we provide "Engine Protection Technology." With access to over 100 grades of filter media and adherence to the 4-micron standard (for Main Filters), we ensure your vehicles and machinery operate at peak performance with maximum reliability.

If you are unsure which filter specification is right for your vehicle or need advice on fuel water separation, please feel free to consult our technical team.