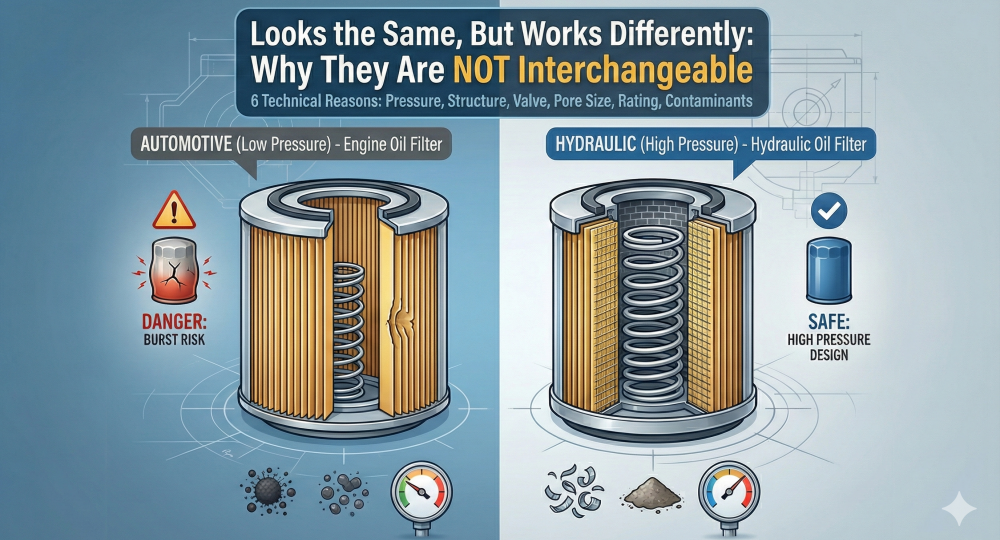

Have you ever stood in front of an auto parts shelf or looked at a "Spin-on" filter and thought they all look identical? The can size is the same, the thread fits perfectly, and the gasket aligns. It leads many to ask: "Can I use a standard automotive engine oil filter instead of a hydraulic filter?"

The answer is a resounding "ABSOLUTELY NOT."

Doing so is like planting a ticking time bomb in your machinery. While they may look like twins on the outside, their internal engineering is completely different. Here are the 6 critical technical reasons why these two filters are not interchangeable.

This is the most critical safety factor.

Automotive Filters: Designed for internal combustion engines where oil pressure is relatively low and flows steadily.

Hydraulic Filters: Must withstand much higher operating pressures. More importantly, they must handle "Pressure Spikes" or surges that occur violently when hydraulic cylinders or actuators cycle.

The Risk: The metal housing (canister) of an automotive filter is too thin for hydraulic applications. If used, it can bulge or burst completely, spraying high-pressure oil everywhere, causing catastrophic fluid loss and potential injury to operators.

Most spin-on filters have an internal safety valve (Bypass Valve) to prevent oil starvation if the filter gets clogged. However, the spring settings are vastly different.

Automotive Filters: The bypass valve is set to open at low pressure (e.g., 10–15 PSI) to ensure immediate lubrication during cold engine starts.

Hydraulic Filters: Require a higher cracking pressure (or sometimes have no internal valve at all) to force the thick hydraulic fluid through the filter media.

The Risk: If you install an automotive filter, the normal operating pressure of the hydraulic system will force the weak bypass valve to stay permanently open. This means the fluid will bypass the filter entirely, circulating unfiltered oil and contaminants throughout your expensive hydraulic components.

Automotive Filters: Typically use Cellulose (paper) media.

Hydraulic Filters: Often use Synthetic (Micro-glass) fibers and, crucially, are reinforced with a Wire Mesh Backing to support the media against high pressure and high-viscosity fluid flow.

The Risk: Without the wire mesh support, the paper media of an automotive filter can collapse under hydraulic pressure. This collapsed media can block oil flow, starving the pump and causing cavitation or failure.

Different Requirements: Hydraulic systems rely on tight-tolerance components (like servo valves) that require specific pore sizes.

The Risk:

If the automotive filter is too fine: It creates high restriction, causing the pump to work too hard or overheat.

If the automotive filter is too coarse: It allows harmful particles to pass through, scoring cylinder rods and damaging seals.

The standard of "cleanliness" differs significantly.

Automotive Filters: Usually rated on a "Nominal" scale. They capture most particles but allow some bypass because engines have higher tolerance for dirt.

Hydraulic Filters: Rated using the "Beta Ratio" (Absolute Rating). They are engineered to capture nearly 100% of particles at a specific micron size to protect sensitive hydraulic valves.

The Risk: An automotive filter is simply not precise enough to protect high-precision hydraulic components.

The "enemy" inside the fluid is different.

Automotive Filters: Designed to hold soot, combustion by-products, and sludge.

Hydraulic Filters: Designed to trap metal wear particles, silica (dust/sand), and moisture.

The Risk: Using the wrong media chemistry means the filter may clog prematurely or fail to capture the specific contaminants damaging your hydraulic system.

Trying to save money by using a cheaper automotive oil filter on a hydraulic machine is "False Economy." The cost of replacing a damaged hydraulic pump or the downtime caused by a burst filter is dozens of times higher than the price of the correct filter.

Protect your machinery and your wallet. Always use the specified Hydraulic Filter for your equipment.